Description

RENZ

Inline 500 Classic

Fully automatic high-speed line for wire comb binding – with perfect round closure

Industrial punching and binding solution offering maximum efficiency and flexibility – ideal for block, calendar, and brochure production up to 500 mm working width.

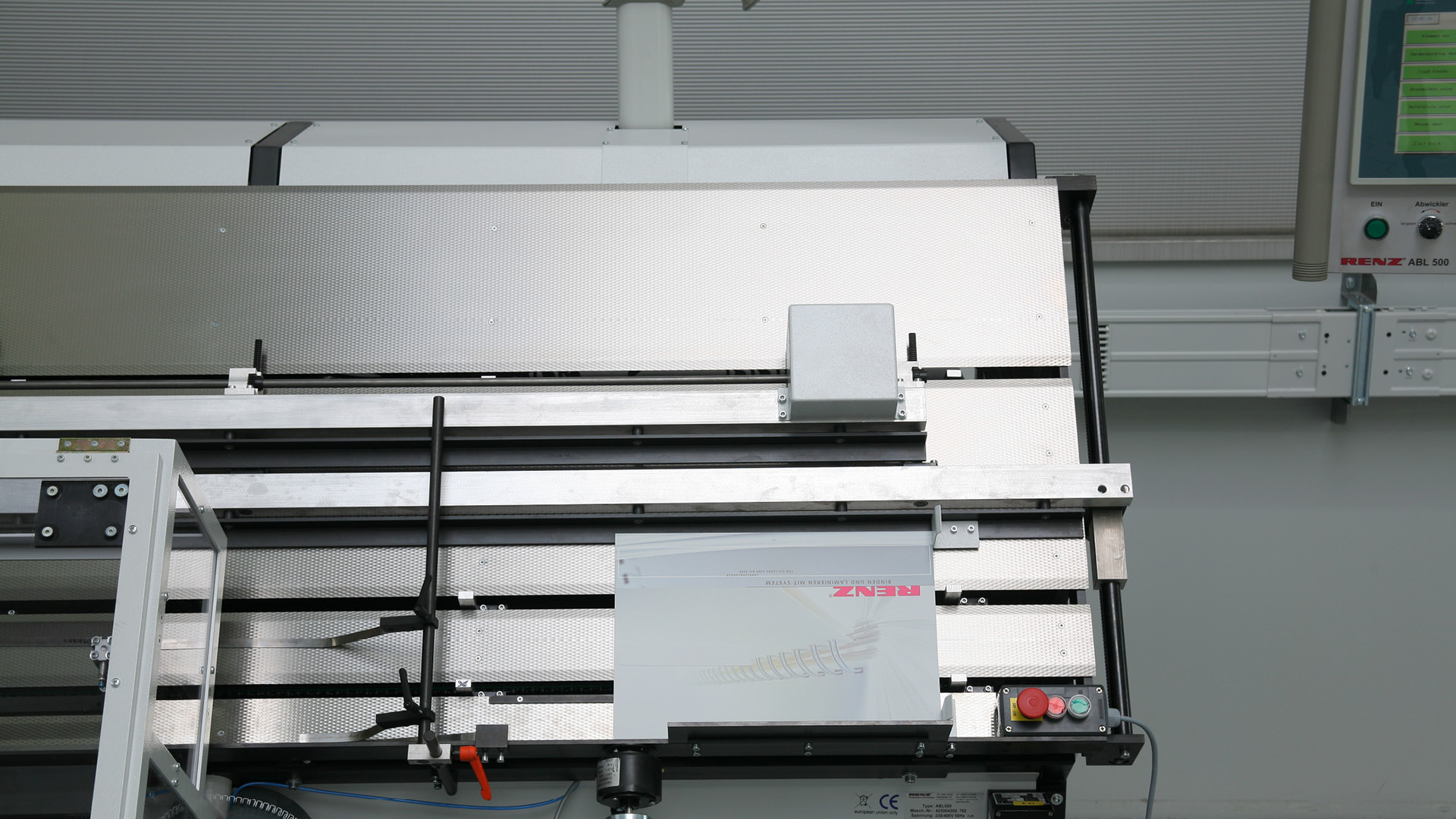

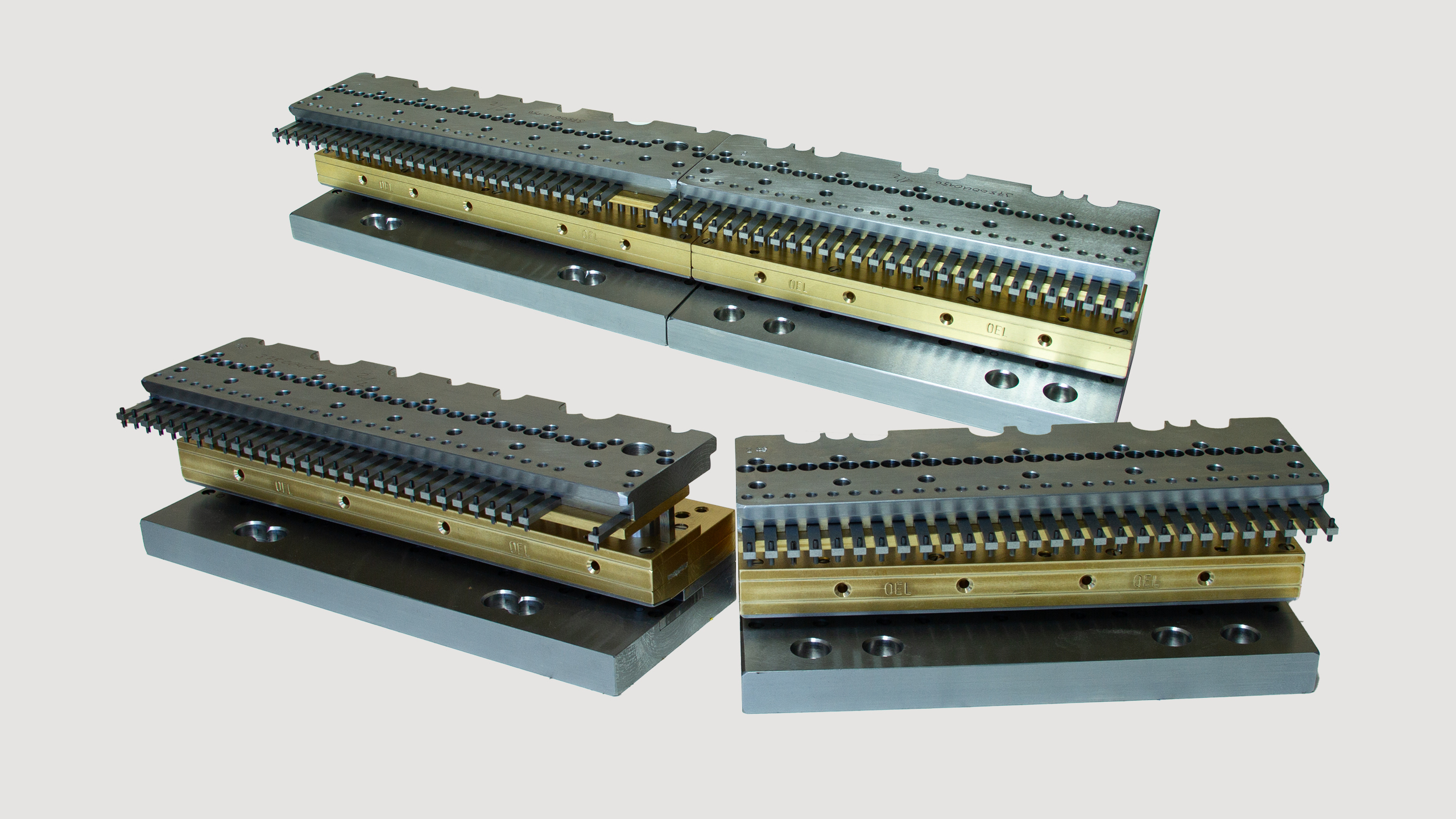

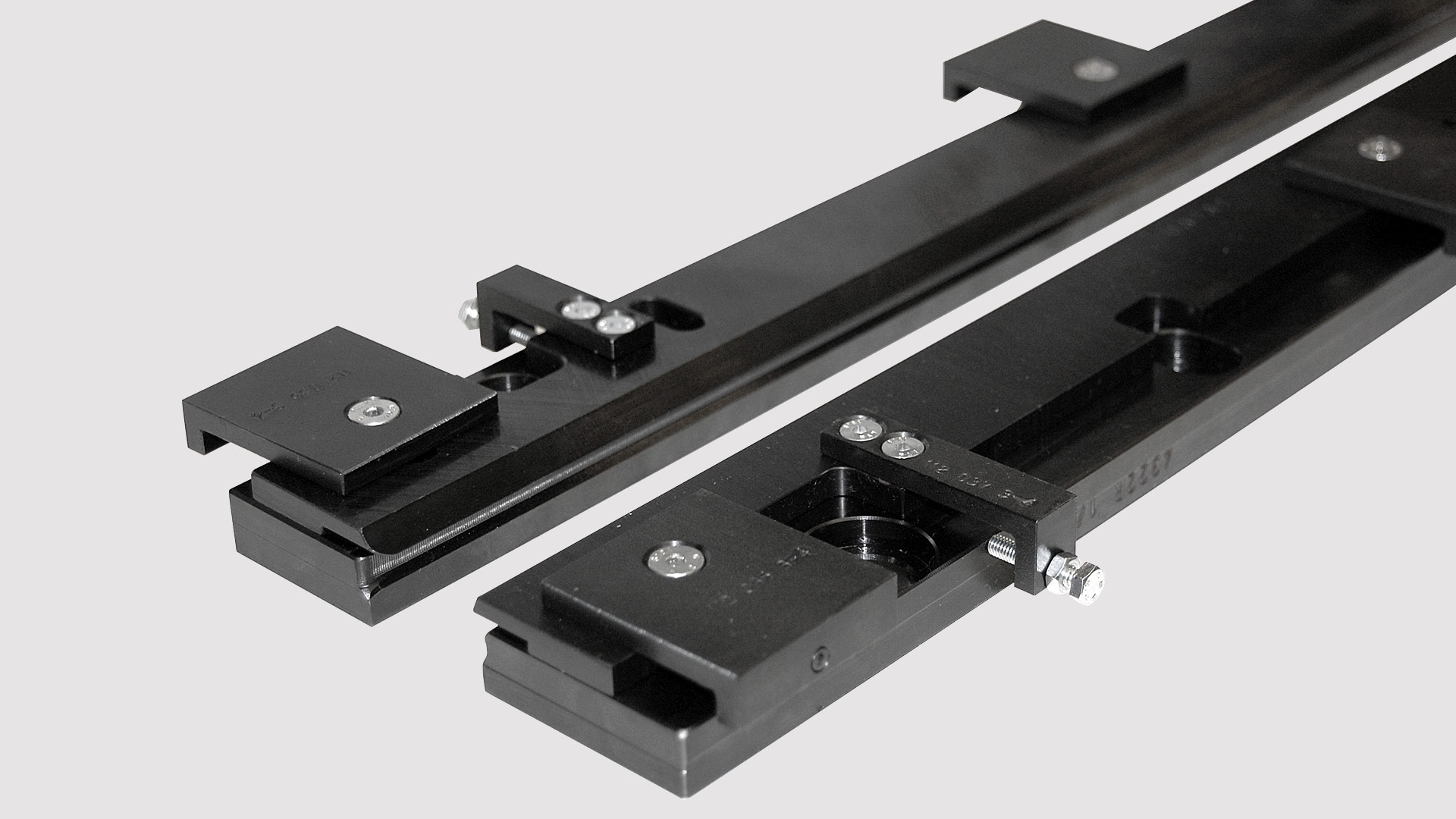

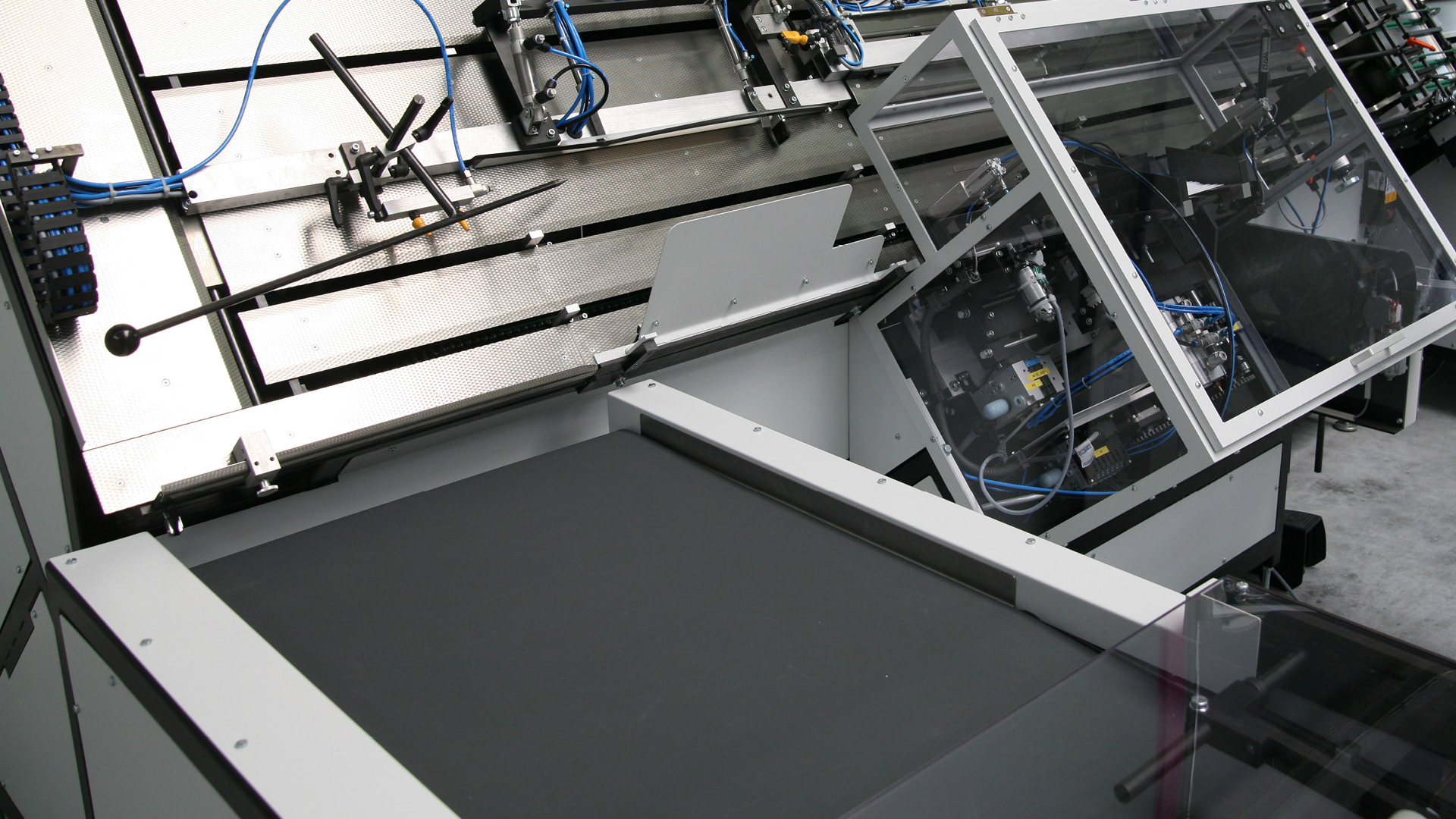

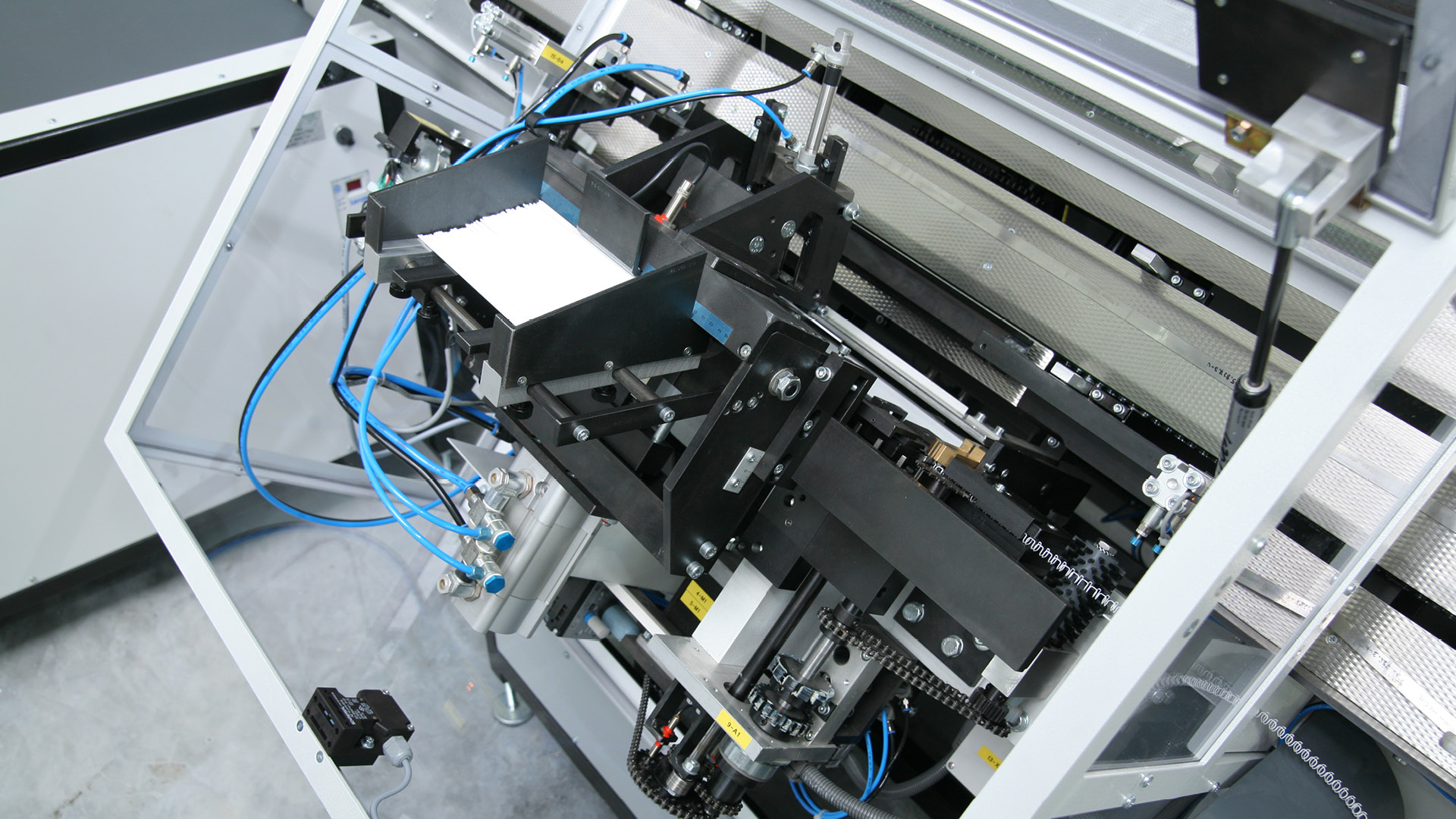

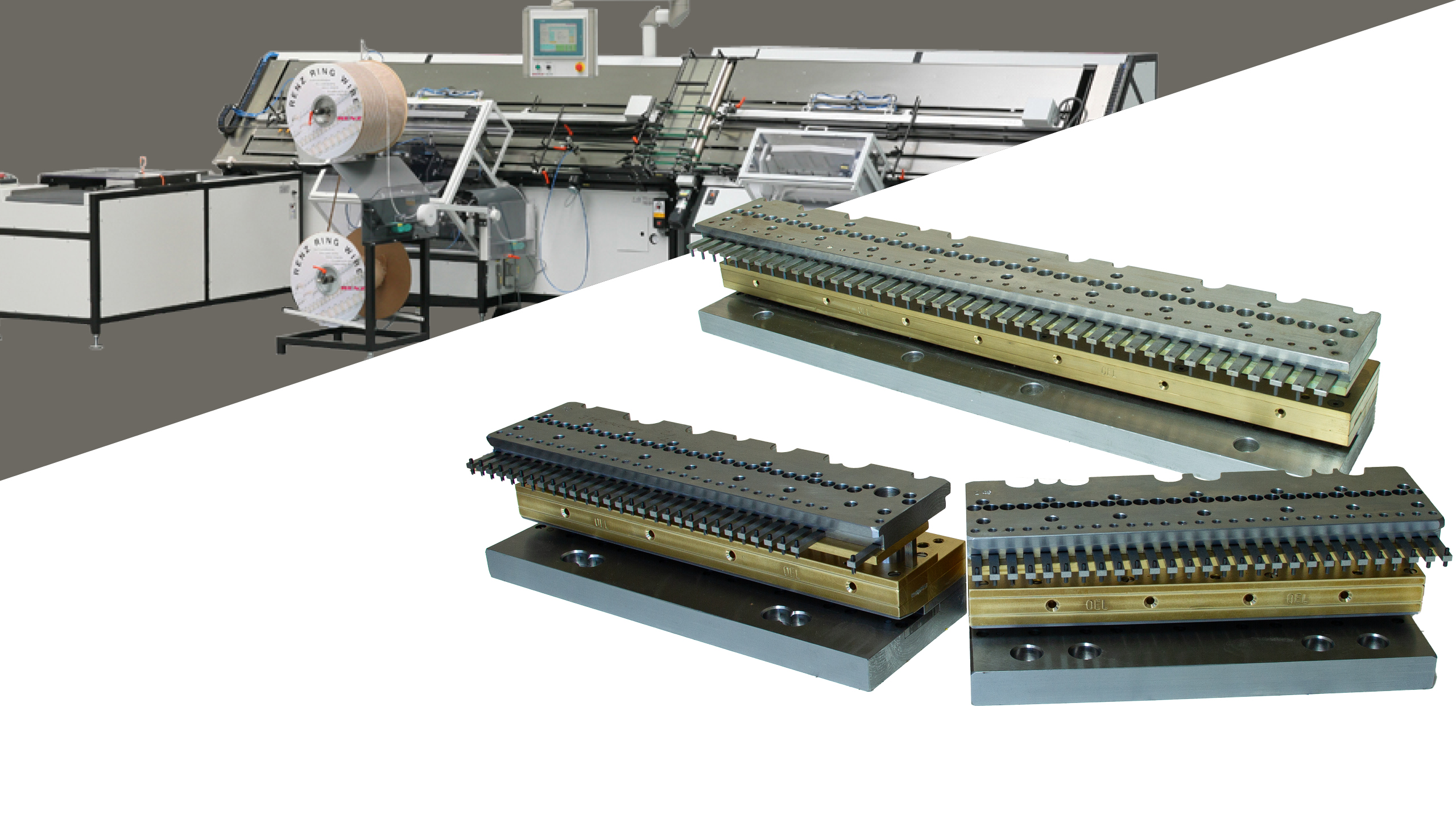

The RENZ INLINE 500 is a fully automatic high-speed punching and binding line designed for industrial wire comb binding applications. It has been developed for the efficient production of calendars, brochures, photo books and pads, handling formats up to 500 x 700 mm with a maximum binding thickness of 15 mm. Thanks to its modular design and high format flexibility, the system is ideal for professional and cost-effective production – even with frequently changing product formats. The system combines a powerful punching module with a precisely operating binding module and features numerous technical highlights: automatic format changeover, short setup times, and a multilingual touchscreen control panel with optional job memory ensure maximum user-friendliness and productivity. For different binding thicknesses, matching closing bars in various sizes are optionally available, guaranteeing a perfect round closure for every wire diameter. In addition, high-quality RENZ punching dies are available with various pitches (e.g. 3:1, 2:1) and punching patterns (e.g. rectangular, round, thumb cut) – suitable for all common applications such as pad, calendar or skip binding. The QSA (Quick Size Adjustment) technology enables the deactivation of individual punching pins directly on the die in seconds – without the need for removal. A wide range of optional extensions – such as the calendar hanger inserting unit KAS 300 IL, the cover turner DBW 500, a cross stacking unit or a thumb hole punch – transform the system into a fully integrated production line with perfect round closure using RENZ RING WIRE® wire combs, manufactured in Germany. With the INLINE 500, you are choosing a reliable, durable and economical solution for industrial wire comb binding – Made in Germany.

Features

- Punching dies for all ring wire, calendars & skip binding

- Versatile calendar production line capable of producing a wide range of formats

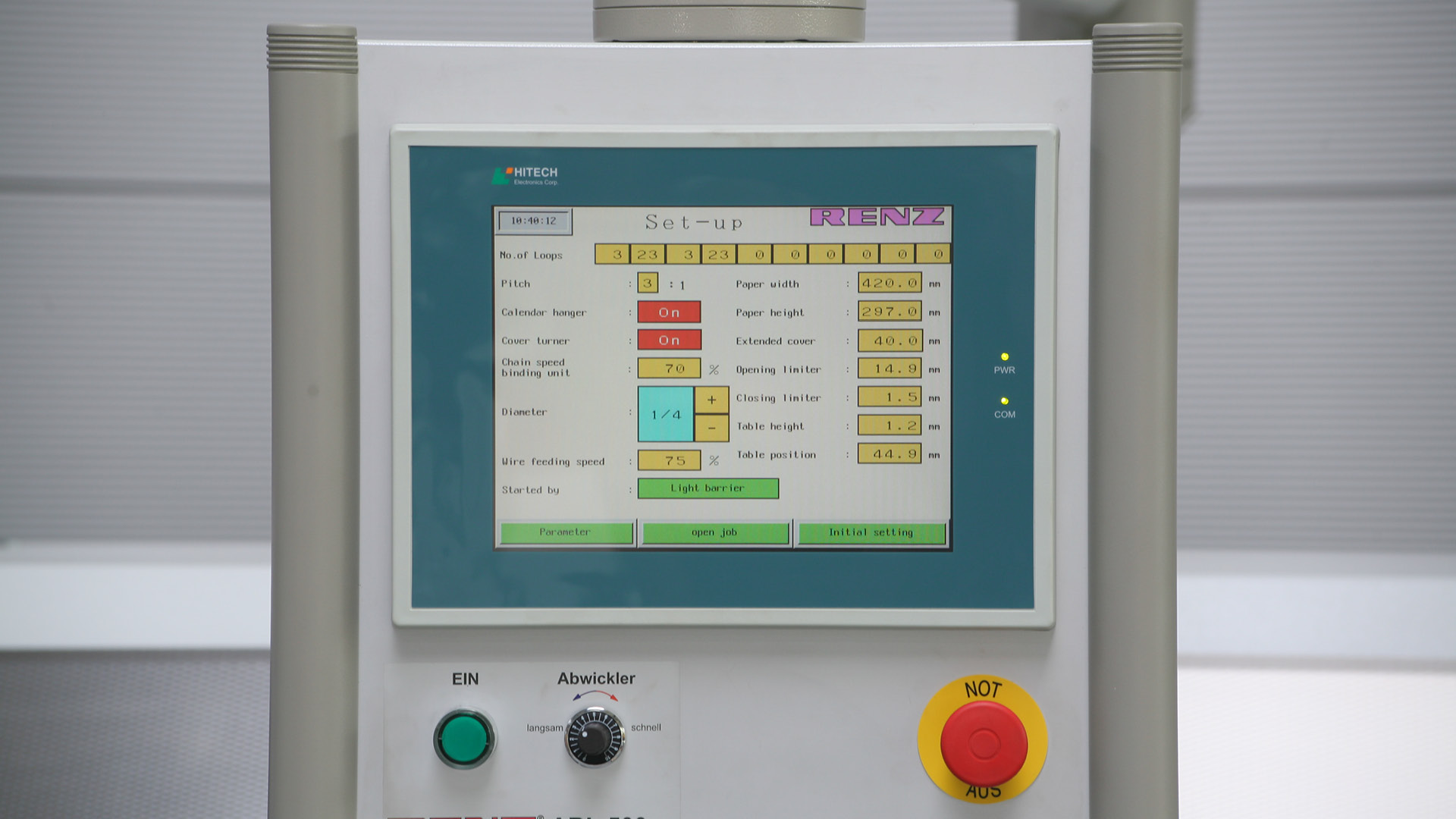

- Simple & fast on-screen machine setup

- Touch screen assisted setup process

- QSA (Quick Size Adjustment) for high flexibility of different paper formats

- Integrated cover page lifting device

- Optional extras:

- Job memory, storage capacity of up to 50 jobs

- KAS calendar hanger systems

- Cover turner

- Cross Layer

- Nail hole punch

Properties

| Product type: | Fully automatic punching and binding machine |

|---|---|

| Field of application: | Wire comb binding, Calendar binding |

| Function: | automatic punching and binding |

| Operation: | Sensor, Foot switch |

| Setup / Settings: | Touchscreen, manuell |

| Format change: | 5 min |

| Diameter change: | 20 – 30 min |

| Working width: | 500 mm |

| Min. format (w x l): | 70 x 135 mm |

| Max. format (w x l): | 500 x 700 mm |

| Pitch: | 3:1, 2:1 |

| Optional punching tools available: | Punching dies available in many pitches, hole patterns and designs: wire comb binding, calendar binding |

| Punching die type: | High-performance punching die |

| Selectable punch pins (QSA): | yes (depending on die) |

| Adjusting margin depth: | variable (dending on die) |

| Multi-part punching dies: | yes (depending on die) |

| Bespoke dies: | yes (on request) |

| Workable diameters: | Ø 1/4“ – 3/4“ (6,9 – 19,0 mm) |

| Max. binding thickness (mm): | 15,0 mm |

| Mechanical cycles /h: | 2500 |

| Max. punching thickness: | 4,5 mm |

| Max. bound items /h: | 2000 |

| Feeding calendar hangers (optional): | KAS 300 IL (80 – 300 mm) |

| Compressed air requirement: | 7,5 bar (450 – 500 l/min) |

| Power requirement: | 400V, 3PH/N/PE, 50Hz, 8kW |

| Power requirement (alternativ): | on request |

| Product size (w x h x d): | 5400 x 1600 x 2500 mm |

| Product weight: | 2400,0 kg |

Learn More / Request Quote

To learn more about this item (Renz - INLINE 500 Classic // Industrial, high-speed, fully-automatic punching and wire comb binding line for books, calendars and skip binding up to 500 mm.) and/or to request a quote, please complete and submit the form below.